By Umar Nsubuga

For the ninth year running, Vision Group, together with the Embassy of the Netherlands, KLM Airlines, dfcu Bank and Koudijs Nutrition BV, is running the Best Farmers Competition.

The 2024 competition runs from April to November, with the awards in December. Every week, Vision Group platforms will publish profiles of the farmers. Winners will walk away with sh150m and a fully paid-for trip to the Netherlands.

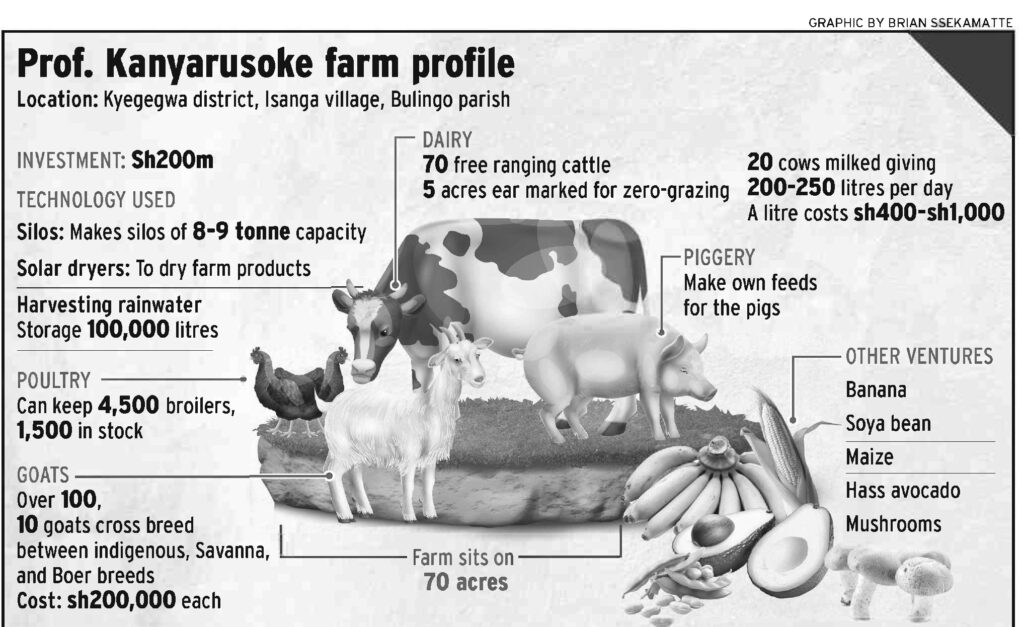

Renewable Energy for Food and Water Engineering Farm Limited was established four years ago and is fast becoming a household name in Kyegegwa district, about 7km off the Kyegegwa-Fort Portal road in Isanga village, Bulingo parish.

It is run by Prof. Kant Kanyarusoke and his wife Sheila Kanyarusoke. The farm has two sections; agribusiness and solar engineering.

How they started

Prof. Kanyarusoke is a 66-year-old engineer and head of chemical and process engineering at Busitema University.

Together with his wife, they had previously worked in foods and chemical factories in Uganda, until they took on a consultancy in Botswana in 2006 to help set up a soap factory.

The couple had acquired land in Isanga and had been using only part of it for subsistence mixed farming. In 2007, South African universities were looking for African engineering lecturers to ease their transformation, Prof. Kanyarusoke saw an opportunity.

“I applied, got the job and worked there for 15 years,” Kanyarusoke says.

While in South Africa, he pursued a PhD in solar energy engineering as he lectured, while his wife enhanced her nursing profession.

Kanyarusoke says they learnt about value addition of both mineral and agricultural products and experienced first-hand rainwater harvesting and purification.

In 2020, Kanyarusoke rejuvenated farming activities at his home. After the lockdown, his wife returned from South Africa to supervise the farm as he worked at Busitema University.

The farm

The 70-acre Isanga farm includes poultry, piggery, goats, maize, matooke, beans, soy, avocados and mushrooms.

They have so far invested sh200m into the farm, money from their retirement packages from South Africa. Cattle and most goats are kept at the ancestral home in Karwenyi, 30km from Isanga.

Technology The farm has several machines, which include a walking tractor for land preparation and planting, solar crop dryers, storage silos, water processing and packaging machinery.

Others are an ice cubes making machine, milk de-creamer and butter chunner, maize micro-processing plant, a feeds-pelleting machine and a micro-briquetting factory.

Most of the machines are made by the engineering division of the company and powered by solar energy.

“Although I have workers, I availed these machines to ease their work,” he says.

There are also machines which chop grass for goats and pigs, a maize mill for feeding the family and workers.

The bran is used to make animal and poultry feeds. At the farm, there is a process of making ab drinking water micro-factory. It has a water ozonator that kills any trace of organisms that may have escaped destruction by triple sterilisation and triple filtration processes.

The water is branded as REFWE Gulps Solar Water. It is now awaiting Uganda National Bureau of Standards certification before circulation.

Silos

The company makes silos of the latest technology for storage, as opposed to traditional granaries. Those seen at the farm have a capacity of eight to nine tonnes of maize, which they can store for over 12 months.

According to records, customers in Kyenjojo district had recently purchased 30 tonne capacity units from the company.

They are made of double jacketed steel, which according to Kanyarusoke, keeps the stored produce at uniform cool temperature, minimising heat-induced damage.

He advises farmers to learn from him to improve their post-harvest handling by owning silos.

Solar dryers

The farm makes solar driers, which are used to dry cassava, mushrooms, jackfruit and other products to increase shelf lives.

“Once I harvest mushrooms, I dry them in the solar dryer, which gives me time to sell them for longer periods,” Sheila says.

Harvesting rainwater

For a farm to be sustainable, it needs a reliable source of water. Managing a farm without water is frustrating.

The couple collects and filters all rooftop water before storage in above-ground and underground 100,000-litre tanks.

The above-ground water is used for normal farm activities, while the 50,000-litre underground tank is mainly for the water-micro factory.

He urges other farmers to value rain water.

Chicken farm

The chickens are housed in a three-storeyed structure that can hold 4,500 broilers. At the time of the visit, he had 1,500 in stock.

Regarding hygiene, Kanyarusoke says cleanliness is the most important part of a poultry farm. Thus, each level has a 10,000-litre tank.

“I do not want workers of different sections to move from one floor to another. Water is pumped to each floor separately,” he explains.

Similarly, the feeding containers and troughs for each floor are not moved to another in order to prevent spread of diseases.

At his farm, he doesn’t allow just anyone to access the structures and he takes care of bio-securities. Birds and people who are not from the farm are not allowed onto the floors.

“At the moment, the birds are sold live, but there are plans to sell them dressed,” he said.

Goats

He says he maintains over 100 goats, mainly at his ancestral home, 30km from Isanga. At the farm, there are 10 cross-breed goats between indigenous, Savanna and Boer breeds. Each cost an average of sh200,000.

“Young females are mated from the age of 12 months,” he says.

Regular deworming reduces incidences of death and slow growth. There are also plans to milk the goats for value addition.

Cattle

The farm has 70 free range cattle — all at the ancestral home. Five acres of Isanga land has been earmarked for zero grazing structures.

Twenty of the 70 are being milked, giving a yield of 200-250 litres per day. The average cost of a litre of milk is sh400-sh800 during the wet season and sh1,000 during the dry one.

Due to the low prices, Kanyarusoke says they ventured into value addition by making ghee that is packed in varying sizes.

Piggery

Before venturing into piggery, Kanyarusoke says; he researched about pigs and learnt that if fed well, one would get a good return.

He then invested in making feeds that consist of maize bran mixed with mukene (silver fish), cotton seed cake, red salt, shells and multivitamins. These are supplemented by cleaned farm produce peelings.

Kanyarusoke says one must have a good breeding stock. Farmers must also pay attention to the market demands.

He adds: “If one has pigs for pork, the males should be castrated and fattened to at least 45kg after four months.”

Soya bean Project

After learning that he could extract oil from soybean, Kanyarusoke started growing the crop on six acres.

He grows Namsoy4 and Maksoy3N, which he says are drought-tolerant and are high yielding. In addition, the crop is resistant to pests and diseases.

An acre takes 20kg of seed and yields 800kg if taken care of well.

“Each kilogramme goes for between sh1,500 and sh2,000, which translates into sh1.2m after investing sh600,000,” he adds.

Soy is grown primarily for the animal poultry and animal feeds. An oil press is being acquired to make oil so that it is only the protein rich cake, which is fed to the animals.

Maize

Kanyarusoke grows maize on 20 acres every season, but does not sell his crop raw. He processes it into various products that include animal feeds and maize flour for sale.

His maize mills are valued at around sh25m. Milling each tonne of maize costs sh1m, since he uses a generator, given that the farm is not connected to the national grid.

He spends sh150,000 on labour, transport and sacks for packing the flour.

Maize flour is largely consumed as steamed and mingled food (posho) or as porridge across Kyegegwa district.

With its high levels of starch, maize bran is a key component of his livestock feeds. The plant is a micro-unit doing 100kg per hour, but is sufficient for the farm’s present needs.

It is also used by neighbours to exchange their maize for flour at an agreed exchange, depending on the quality. There are plans to run it on solar power, instead of diesel.

Hass avocado

Although Hass avocado is a priority crop and there is a push to boost its export, Kanyarusoke doesn’t sell it raw, but makes many products from it.

“The seed has medicinal value and its pulp is used to make oils. These are mostly used in the cosmetics industry and phytochemicals,” he says.

Cosmetics oil, animal feeds inputs, avocado tea and bio char briquettes are the main products he gets for now. Except for oil and tea powder, the others are currently being used at the farm. Oil is sold to cosmetics companies.

Mushrooms

A kilogramme of value-added mushroom packet gives Kanyarusoke sh16,000 and the raw one generates sh5,000.

Briquettes

Waste, such as maize cobs and banana peels and rotten avocado, among others, Kanyarusoke says do not go to waste.

Banana shamba

Kanyarusoke’s banana shamba sits on five acres.

It is mainly for farm use and in-house value addition. Some is dried and turned into flour.

He sells over 20 bunches of matooke every three weeks between sh15,000 and sh20,000 each. There are plans to peel and pack the product for restaurants in Kyegegwa.

Book keeping

“We keep separate records for each of the departments. For example, the maize unit records are kept separately from bran,” Kanyarusoke says.

“We pay workers money in terms of salaries and allowances on the farm. Sales people are paid in proportion to their revenue generation. All permanent workers live at the farm and receive free medical support,” he added.

Main challenges

“Modern agricultural mechanisation is now the way to go, because by using the mechanised tools, you will be able to reap more, but I am the only one in the area, yet I also lack enough mechanised tools,” Kanyarusoke says.

He adds that REFWE is soldiering on amid lack of a grid supply, which means he has to rely on expensive diesel power for some machines.

He says on top of price fluctuations, the weather has become erratic, making farming more expensive.

What others say

Paul Mukonyezi farm Manager

Because of the farm’s activities, my mindset has changed. We pledge to put into practice the lessons learnt and ensure we have good products, such as REFWE.

Lydia kusiiMa, resident

REFWE farm will help our local farmers to acquire knowledge on modern farming methods, because the Kanyarusokes are investors who help the poor with knowledge.